Roofing Systems

Roofing Systems

As Maurer Roofing has evolved, so have the commercial roofing products that Maurer Roofing offers and installs. The old standby, traditional built-up and gravel, is still one of the most tried and true roofing methods available. Modified bitumen systems have a long track record. Maurer Roofing is one of the few companies around that still offers both of these built-up roofing systems as part of our roofing options. We are well equipped to install built-up roofs with either hot or cold process techniques and our veteran crews have many years of experience with built-up roofing system installations. Maurer Roofing is also well versed in many of the single ply systems on the market today. From mainstay EPDM systems to the latest in TPO, PVC, or PIB systems, Maurer Roofing installs all types of single ply membranes. The following paragraphs list and explain many of the products and systems that Maurer Roofing handles. Call us today at 715-387-2570 to discuss which system is best suited for your re-roof or new construction project.

Standard EPDM or “rubber” single ply roof systems

EPDM

Single ply EPDM, ethylene propylene diene monomer, or “rubber” roofing is far and away the most popular roofing system in use today. EPDM membranes are thermoset products which means the membrane is chemically cross linked (taped or liquid adhesively seamed) to form a monolithic surface. They are the most widely used roofing material used today with millions of square feet applied annually all over the world. Developed in the 1960’s EPDM has established a long and proven track record, is relatively inexpensive, and is fairly simple to work with. Installation methods including ballasted loose-laid, mechanically attached, and fully adhered systems the most common systems installed. EPDM roofs come in a wide variety of thicknesses from 45 to 90 mils and can be furnished in cured, un-cured, reinforced, un-reinforced, or fleece back options. One of the biggest benefits in EPDM membranes are in the stock sizes available from 10’ x 50’ up to 50’ x 205’ and larger, making installation of expansive roof areas rather fast. The membranes are available in black and white colors. Roofing accessories such as boots and reinforcing edge strips are widely available for EPDM membranes and they help make the EPDM systems quick to install. Carlisle-Syntec, the leader in single ply roofing systems, supplies Maurer Roofing with its proven “Sure-Seal” EPDM membranes. Carlisle’s trained technical reps provide assistance to Maurer Roofing in writing specs and help us in designing roofs that can meet an array of FM Mutual and UL Listing requirements for wind uplift and fire ratings. Carlisle-Syntec offers a wide array of warranty options up to 30 years. Maurer’s field crews are experienced and well trained in all aspects of single ply EPDM systems.

Specialty membrane single ply roof systems

Specialty single ply membranes come in either thermoplastic (heat or solvent weldable) or thermoset (typically tape or liquid adhesive seamed) systems and are becoming widely accepted throughout the roofing industry. Maurer’s installs a wide array of these specialty roofing products.

TPO’s

TPO, or terpolymer olefin, membranes have gained a fair amount of market share. TPO membranes, which are an ethylene propylene based rubber product, combine the characteristics EPDM and PVC. The membranes typically have a reinforced scrim layer that gives it good strength, wearability, and puncture resistance. Many of the earlier formulations had tendencies to fail at seamed areas or breakdown due to UV exposure or some of the fire retardant additives used. These issues have been resolved over the years and TPO’s have become a very reliable product. TPO, because of its flexibility, is a great fit for odd shaped roofs such as fan folds or barrel roof profiles. They have excellent chemical resistance characteristics and are excellent membranes for restaurant roof systems and other areas where high concentrations of chemicals, grease, and animal fat contamination are present. TPO is generally available in light colors including white, tan, and gray. TPO systems have heat welded seams and are sometimes marketed as a “seamless” roof due to the bonding that the heat welds create. TPO systems can be mechanically attached or fully adhered and on rare occasions they are loose-laid and ballasted. Maurer Roofing features Carlisle’s 10’ to 12’ wide “Sure-Weld” TPO membranes, the widest available sheet stock of TPO membrane offered in the roofing market today.

PIB’s

PIB or polyisobutylene membranes, are another of the new age single ply membranes. PIB membranes, a synthetic rubber based product, are similar to TPO’s with the exception of the seaming method. Maurer’s handles both Geoflex and Tremco PIB’s.

PVC’s

PVC or polyvinyl chloride, Maurer Roofing handles Johns-Manville UltraGard PVC membranes.

Built-up or “BUR” roof systems

Traditional BUR

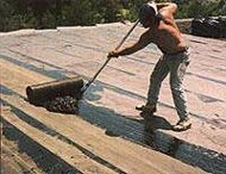

Tradition built-up roofs have been around since the 1840’s. They typically consist of a base sheet and multiple layers of saturated felts or other fabrics that are mopped down in hot or cold liquid. The liquid adhesive can either be hot asphalt, hot coal tar, or cold solvent based asphalt. The felts are typically 3 to 5 overlapping plies thick and are covered with either gravel or slag embedded in a flood coat or with a granulated cap sheet which is mopped down over the underlying plies of the roof. Details such as flashings and curbs need special attention to ensure a monolithic transition between the roof deck and curbs or parapets. A basic rule of thumb for the life expectancy of a built-up roof is 5 years per ply. For example, a 3 ply roof system properly installed will last approximately 15 years, a 4 ply system for 20 years, and a 5 ply system for 25 years. These life spans are general observations and can vary greatly depending on the quality of the materials and installation, the location and climate of the area the roof system is installed in, and the amount of foot and equipment traffic the roof sees among other factors.

Modified Bitumen BUR

Modified bitumen roof systems are similar to BUR in that they typically consist of a base sheet and multiple plies of material to form the water tight roof covering. There are two types of modified bitumen membranes, APP (atactic polypropylene) or SBS (styrene butadiene styrene). APP membranes are typically 3’ wide rolled membranes that are torched down which allows the back of the membrane to bond to the substrate below it. APP systems work great for roofs that are cut up and do not have a good access or working space. SBS membranes are also 3’ wide rolled membranes that have a reinforcing scrim or mat made up of polyester or fiberglass. SBS can be installed in hot asphalt, torch applied, or installed in cold liquid adhesive.

When looking at installing a BUR or Modified Bitumen system care must be taken to assess the structural design of the roof framing and the type of roof deck that the system will be installed on. There are many types and grades of asphalts, coal tars, lap cements, and solvent based asphalt products that are used in BUR systems. BUR roofs are excellent systems to use when a vapor barrier system is required. Typical BUR applications include industrial facilities such as paper mills and power plants. These systems, while having a long and proven track record, must only be installed by highly skilled roofers with the proper experience, knowledge, and training. The employees at Maurer Roofing possess these vital qualifications for installing BUR systems. We install Tremco, Garland, and many other BUR systems.